How are the thermal bonding steps performed during the production of Antique stone coated metal roofing tiles for ancient buildings scenic spots?

The thermal bonding steps during the production of

antique stone-coated metal roofing tiles for ancient buildings and scenic spots are crucial to ensuring the proper adhesion of the stone granules to the steel substrate. These steps involve the application of heat to activate the adhesive and securely bond the granules to the steel surface. Here's a general overview of how these thermal bonding steps are typically performed:

Application of Stone Granules: After the steel coil has been coated with the adhesive, a layer of natural stone granules or ceramic-coated granules is evenly spread or sprayed onto the adhesive-coated steel sheet. These granules are pre-colored to achieve the desired antique appearance.

Roller Pressing: The steel sheet with the stone granules is then passed through rollers that apply pressure to the surface. The rollers serve

multiple purposes:

They press the stone granules firmly into the adhesive, ensuring proper contact and bonding.The pressure from the rollers helps to evenly distribute the granules across the surface, preventing gaps or unevenness.This pressure assists in the initial bonding process.

Heat Application: Following the roller pressing, the steel sheet with the stone granules is subjected to heat. The heat serves several critical functions:

Activation of Adhesive: The heat activates the adhesive that holds the stone granules in place. This softens the adhesive and allows it to flow and bond the granules securely to the steel substrate.

Curing: The heat helps cure the adhesive, ensuring that it hardens and sets properly. This curing process contributes to the long-term durability of the roofing tiles.

Bonding: The combination of pressure and heat during this step results in a strong and lasting bond between the granules and the steel surface.

Cooling and Setting: After the thermal bonding process, the steel sheet with the bonded stone granules is allowed to cool and set. This cooling phase helps ensure that the adhesive solidifies and the bond becomes stable.

Quality Inspection: Following the thermal bonding and cooling, the roofing material is subject to quality control measures. Inspectors assess the appearance, bond strength, and overall quality of the stone-coated surface to ensure that it meets the manufacturer's standards and specifications.

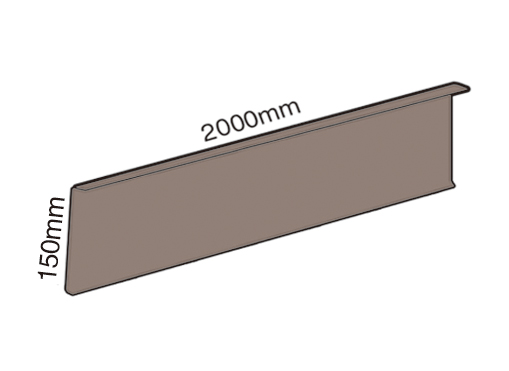

Cutting and Shaping: The continuous sheet of stone-coated steel is then cut into individual roofing tile shapes. These tiles are formed with the desired antique appearance, and their profiles are designed for interlocking during installation.

How to create various patterns and textures on Antique stone coated metal roofing tiles for ancient buildings scenic spots?

Embossing and Texturing: One of the primary methods for creating patterns and textures on stone-coated metal roofing tiles is embossing. This process involves pressing the roofing material between rollers or molds with specific patterns and textures. The pressure applied during embossing transfers the desired pattern onto the surface of the tiles.

Customized Molds: Manufacturers can create customized molds with intricate patterns and textures to achieve unique designs. These molds are used during the tile-forming process to impart the desired appearance. Custom molds allow for a high degree of creativity and customization in the design of the roofing tiles.

Handcrafted Techniques: In some cases,

antique stone-coated metal roofing tiles may undergo handcrafted techniques to create irregularities and variations in texture. This can include manually distressing or texturing the tiles to achieve an antique look. Handcrafted methods add a level of authenticity and uniqueness to the roofing tiles.

Surface Coatings: Specialized surface coatings or finishes may be applied to the roofing tiles to enhance their texture and appearance. For example, a patina or weathered finish may be added to simulate the effects of aging on the surface, giving the tiles an antique look.

Layered Stone Granules: The stone granules applied to the surface of the roofing tiles can be layered to create depth and texture. Different-sized granules or granules with varying colors can be strategically placed to achieve a textured appearance.

Natural Stone Blending: The selection and blending of natural stone granules play a significant role in achieving the desired patterns and textures. Manufacturers often carefully choose and combine stone granules to mimic the look of aged or weathered materials.

Color Variation: Variations in color and shading across the roofing tiles contribute to their textured appearance. Manufacturers use different shades and hues of stone granules to create a visually rich and dynamic surface.

Antique Finish Techniques: Techniques such as antiquing, distressing, or staining may be applied to the surface of the roofing tiles after they have been formed. These techniques can simulate the effects of time and weather on the tiles, enhancing their antique appearance.