Product Consultation

Your email address will not be published. Required fields are marked *

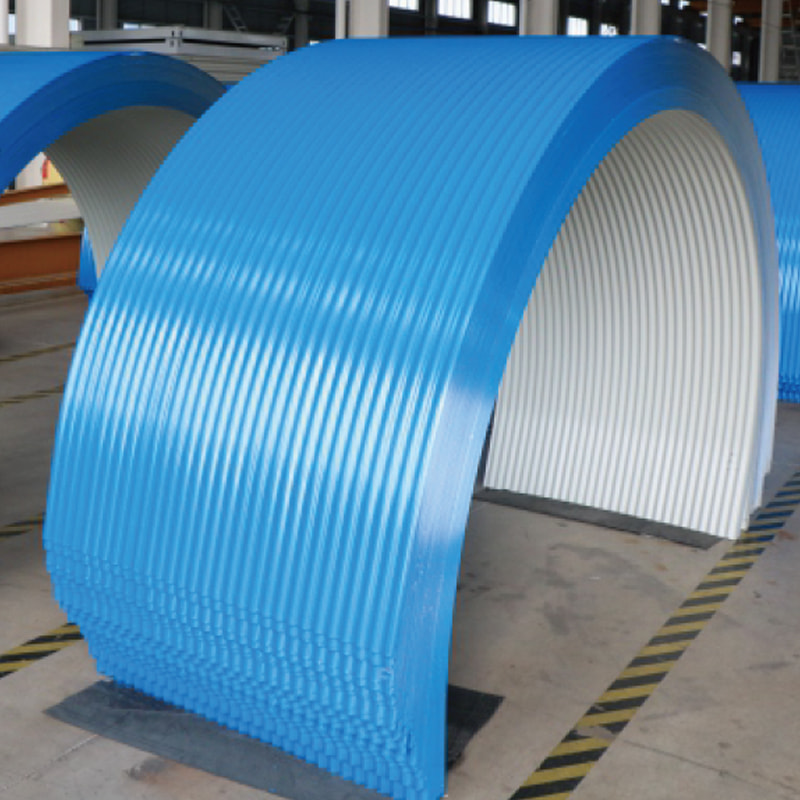

How Crimp Curved Sheets Optimize Roof Design and Performance in Modern Metal Shed Panels

Jun 12,2025

Unlocking Design Potential with South Africa Tile: How Size and Thickness Inspire Innovative Interior Architecture

Jun 06,2025

Eco-Friendly Roofing Solutions: Why Stone Coated Wood Style Roof Tiles Are Greener Than Timber

May 26,2025In modern industrial and architectural design, curved roofing elements have become more than just a stylistic choice—they’re a functional necessity in many complex roof structures. Among the most versatile solutions are crimp curved sheets, which integrate seamlessly into metal shed panels to accommodate unique design challenges. These components offer engineers and builders a precise way to manage water runoff, enhance wind resistance, and maintain structural consistency, all while achieving a visually cohesive finish that blends with the rest of the cladding system.

Crimp curved sheets are manufactured through a cold-forming process where precise crimps are introduced to enable sheet flexibility and controlled curvature. This technique allows panels to conform to curved rooflines without sacrificing material strength. Unlike standard bending, crimping maintains consistent cross-sectional integrity, minimizing the risk of micro-fractures and ensuring longevity under environmental stress. When properly applied, these sheets provide a continuous surface that directs rainwater efficiently into integrated drainage systems, protecting both the roof and the internal structure from water damage.

From a design engineering standpoint, the ability to specify exact radii of curvature gives architects and project managers considerable control. Whether you're covering domed conveyor shelters or semi-circular warehouse extensions, the customizability of crimp curved sheets within a metal shed panel system ensures that the roof elements meet both structural load requirements and visual expectations. This adaptability is especially valuable in retrofitting applications where compatibility with existing structures must be tightly managed without full redesigns.

The role of these curved components becomes even more critical in regions with high rainfall or heavy snow loads. A properly curved sheet not only helps reduce standing water but also channels runoff into gutters with improved flow dynamics. When integrated into a full metal shed panels solution, the result is a unified system that mitigates leaks, reduces ice dam formation, and extends the life of the roof. In contrast, systems using flat or angular panels in curved areas often experience stress concentrations that can lead to early material fatigue.

Installation expertise is also a key factor in maximizing the benefits of curved sheet applications. Precision in matching panel radii with subframe tolerances ensures smooth alignment and prevents performance degradation over time. Experienced manufacturers provide not just the product but also detailed technical support, including layout guidance, fastener placement strategies, and transportation recommendations to preserve shape fidelity during delivery. Working with a supplier who understands these field conditions makes a significant difference in final project quality.

For businesses specifying metal shed panels in sectors like logistics hubs, agricultural depots, or even sports arenas, crimp curved sheets represent an intelligent blend of engineering and visual harmony. They provide not only the flexibility to accommodate advanced roof shapes but also the mechanical reliability to stand up to demanding environments. At LAGOS, we’ve refined this production over years of hands-on industry experience, helping partners across diverse sectors meet deadlines and exceed structural goals with confidence.

No previous article

Jan 01,1970

Unlocking Design Potential with South Africa Tile: How Size and Thickness Inspire Innovative Interior Architecture

Jun 06,2025Your email address will not be published. Required fields are marked *

Thickness: 0.4mm

Coverage area: 2.4pcs

Unit area weight: 5.9kgs/sqm

Tile size: 1280 * 420mm * 0.4mm

Installation size: 1220 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6.2kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 0.455pcs

Unit area weight: 2.8kgs/sqm

Tile size: 730 * 740mm * 0.4mm

Installation size: 650 * 700mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 1.67pcs

Unit area weight: 7.2kgs/sqm

Tile size: 1700 * 420mm * 0.4mm

Installation size: 1640 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 2.8kgs/sqm

Tile size: 600 * 740mm * 0.4mm

Installation size: 540 * 680mm * 0.4mm

Thickness: 0.4mm

Tile size: 790 * Nmm * 0.4mm

Effective area: 700 * Nmm * 0.4mm

Name: Color steel curved tile

Steel thickness: 0.5-0.8mm

Model: YX28-205-820/1025

Advantages and Characteristics:

High strength: The toughness and strength of steel plates are very high, which can withstand wind and heavy pressure without deformation or fracture.

Self-cleaning ability: The steel plate surface is treated with a special coating to ensure smooth drainage and prevent sewage accumulation, with a clean and beautiful appearance design. The appearance design of the steel arc-shaped tile is beautiful, which can make the building more fashionable and modern.

The use of roof drain pipes in conjunction with steel buildings can make steel buildings more integrated, simple and elegant. A variety of supporting accessories are provided to meet various installation requirements. Compared with ordinary PVC pipes, they have better high and low temperature resistance and weathering resistance.

Our roof drain pipes can be customized according to the specific structure and design requirements of the building, including parameters such as pipe diameter, pipe length, curvature, etc., which can be flexibly designed to fully adapt to the drainage needs of various irregular buildings and improve drainage efficiency.

If you are interested in our Metal Roofing Tiles, please consult us.

Address :Dagong Town, Haian County, Nantong City, Jiangsu Province of China

Tel/WhatsApp: +86-15265997346

Email: [email protected]